Wonderware, a business unit of Invensys, today announced the release of the Wonderware Industry Pack for Water & Wastewater designed to enhance overall productivity in facility operations for the water and wastewater industry. This is the first in a series of Industry Packs to be introduced by Wonderware that will focus on specific vertical market segments. Wonderware is providing a single unified software platform for integrating real-time information with business critical applications.

The Wonderware Water & Wastewater Industry Pack, which will be available to download for customer support members later this month, is a pre-configured set of application templates and graphics specifically built for use by water and wastewater companies and municipalities. Pre-configured content enables system engineers to minimize the overall cost and complexities associated with creating and managing water and wastewater systems. In addition, it will address critical issues facing this industry such as workforce attrition, regulatory requirements, business factors, source water supply and aging infrastructure.

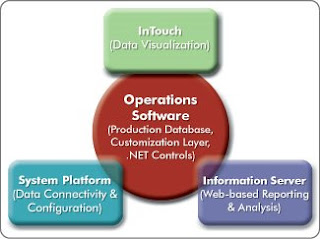

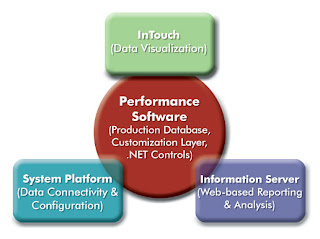

Targeting municipal water and wastewater operations as well as industrial water and waste treatment, the Wonderware Industry Pack leverages ArchestrA technology for greater productivity and ease of use. The unified ArchestrA software architecture simplifies the reporting and management functions performed by operations personnel, enabling them to build systems that are easy to replicate at multiple industry sites.

“There are many companies today that provide SCADA and HMI solutions for the water and wastewater market, but the industry requires a comprehensive solution for the more demanding environment of today’s municipalities,” said Rob McGreevy, director of the Wonderware industry marketing group. “Wonderware offers a refreshing alternative to traditional SCADA system solutions by adding industry specific content and applications on top of the Wonderware System Platform 3.0 software built on ArchestrA technology. This technology enables the integration of applications across all departments and functions to create a comprehensive real-time operations management environment built for the modern municipality.”

For manufacturing environments, synchronization of water treatment systems with overall manufacturing operations provides greater operations efficiency and regulatory compliance. Wonderware software can integrate most any data source, and transform raw data and events into meaningful information that helps reduce operations costs, identifies hidden inefficiencies and enables more cost-effective operations. Extensive flexibility and scalability enables users to expand operations or change work processes as their operational requirements change.

“The ArchestrA architecture is ideally suited for water and wastewater applications by employing an easy-to-use, component-object-based environment for developing standardized water and wastewater operations management solutions,” said Eduardo Ballina, industry manager for Wonderware SCADA solutions. “This significantly improves productivity and controls the overall cost of managing and deploying solutions.”

More than 28,000 Wonderware software licenses are in use at water and wastewater sites around the world to manage plant operations. Offering one-click software upgrades since 1990, Wonderware ensures that water system operators can continue to depend on the experience of a proven software platform and personal support through a worldwide network of local distributors and systems integrators. This provides flexibility both in the way solutions are built as well as in the ability to choose how to implement and maintain systems.